Will New Refrigerant Rules Impact the Design of Your Building?

On September 26, 2016 the U.S. Environmental Protection Agency issued new bans on refrigerants used in HVAC&R equipment. These rules further regulate refrigerants on the basis of their ODP and GWP. If you are not sure what those acronyms mean, the best thing to do is ask a LEED accredited professional, especially one of the new crop of LEED-APs in our office – Hurray to all you LEED APs!

But I’ll give you a hint: ODP stands for Ozone Depletion Potential, and GWP stands for Global Warming Potential. These are scores assigned to a range of chemicals; many used in HVAC&R equipment. We are all familiar with the Montreal Protocol which banned the use of CFCs, and the phase out of the next group of refrigerants known as HCFCs. This left us with the refrigerants widely in use today which are HFCs such are R-134A, R-410-A, and R-407C. (Yes, there will be enough alphabet acronyms in this article to make your eyes glaze over.) Well the newest regulations from the EPA now ban the use of these widely used refrigerants.

Before you start to panic, this is not like the repeal of Obamacare. The phase-out takes place starting January 1, 2024, which gives the industry plenty of time to come up with viable alternatives. As with past refrigerant phase-outs, this will likely lead to more innovation in the HVAC&R industry, but there are challenges to the next generation of refrigerants and equipment that remain to be solved.

The push to maintain high equipment efficiency while reducing refrigerant environmental impact is leading equipment manufactures to look at a class of refrigerants based on HCFOs: hydrochlorofluoroolefins – it’s a mouthful, so I’ll just use letters. This family of refrigerants includes HCFOs, HFOs, and HFO blends.

The main advantage of this new class of refrigerants is that they have a much shorter atmospheric life; measured in days, not years. Many do not survive long enough to reach the ozone layer in the stratosphere, which is a good thing. These next generation refrigerants operate at lower pressure which is good for efficiency, but lower pressure impacts the size of the equipment. The HVAC&R industry has traditionally worked with a variety of refrigerants and operating pressures to get the most efficient systems from the smallest compressor packages. This often meant small units working at relatively high pressures to deliver efficient results. Layering in the variable for environmental impact makes the equation more challenging.

This new class of olefin-based refrigerants is slightly more flammable than current refrigerants which complicates the process further. Current standards rank refrigerant flammability in three classes; class 1 (non-flammable), class-2 (low-flammability), and class-3 (highly flammable). Equipment manufacturers mostly tend to offer class-1 refrigerants in their products. As this new generation of olefin-based refrigerants is being incorporated into equipment design, a new sub-classification has been added: class-2L; defined as slightly flammable. Too much information yet?

I’ll cut to the chase; this new generation of refrigerants will be much better for the environment, can improve equipment efficiency, but may impact the size of equipment and change the design of equipment to provide better flammability protection. This is not so much an issue for Building rooftop equipment, but may impact the size and design of your refrigerator.

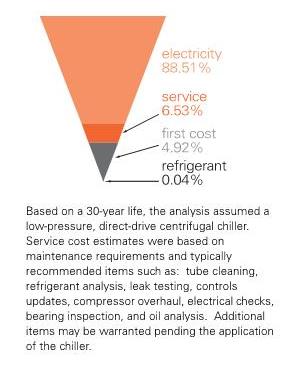

As a side note, look at the cost pyramid of typical chiller: Over a 30 year lifecycle, the cost of equipment is only 5% of the overall lifecycle cost. 6.5% is the cost to maintain it, and 88% is the cost to operate the piece of equipment. It’s not about first cost! Investing in better efficiency equipment is the smartest investment a building owner/operator can make.

The building industry will adapt to these new requirements. Every new green technology has led to healthier, better performing buildings. The HVAC&R industry will use this challenge to improve the design and performance of its products. Architects and engineers will continue to integrate new standards for performance into innovate designs. Our industry rules of thumb will have to change; better to start planning now.

image courtesy of Trane